Surface treatment prevents or delays corrosion (rust). Here are some reasons for why we use surface treatment.

PBI have approved vendors to handle all the plating requirements i.e. Silver Plating, Gold Plating, Copper Plating, Nickle Plating, Tin Plating, Chrome Plating, Brass Plating etc.

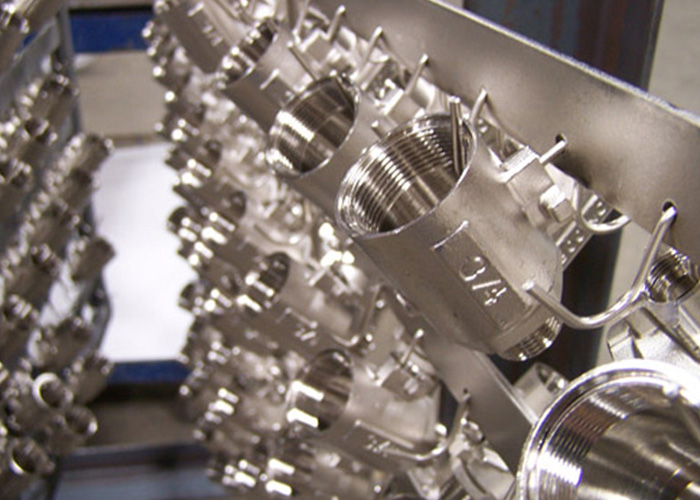

Types of Surface Treatment offered by PBI

- Nickel Plating - Nickel is done after copper plating on Brass for better bonding. We offer Nickel plating up to 50 microns with test reports.

- Chrome Plating - Chrome Plating is done after Nickle and Copper as base plating. This is mainly done for aesthetic purpose in Sanitary and Plumbing Parts.

- Silver / Gold Plating - Silver / Gold Plating is done after copper plating on brass for better bonding. We offer plating as per customer specification with test reports.

- Brass Plating -Brass Plating is done on Steel as well as Brass.

- Tin Plating – Tin Plating is done after copper plating. For better results, it is advisable to do Nickel Plating on Copper and then do the Tin Plating.

- Grinding/Buffing – We do Grinding-Buffing to remove the lines, dents, scratches etc. and to create a bright surface finish. This is normally done for aesthetic purpose.

- Annealing – Annealing is a process that heats the Brass to make it softer and more ductile, effectively reversing the work hardening process. We offer this service based on customer requirement.

- Stress Relieving – Stress relieving is normally done to relieve stresses developed during processes. We offer this service based on customer requirement.